Structural Engineering is a small but critical part of the engineering for a rooftop solar project. It can make or break the feasibility of the project or have significant effects on the system size and cost of racking.

In this article, Pure Power's in-house structural engineering team shares the high level process involved in the structural analysis of a rooftop solar project. We wont get into any calculations, leave that to the professional engineers at Pure Power.

Three Main Steps to Determine the Structural Feasibility:

There are three steps to finalize the structural feasibility for any roof-mounted solar project. In this section, each one of these three steps will be explained in detail.

- Determine the capacity of the current roof framing elements.

In this step, all roof structural elements should be analyzed and investigated to determine their load carrying capacities. Both new and existing roof frames should have enough capacity to safely accommodate the additional load imposed from the installation of the solar system. The additional PV system weight can be incorporated in the design during early stage of the project life. The process is more complicated for existing building. Detailed information pertaining the roof structural element should be available to accurately evaluate those elements load carrying capacities. This information can be found in the original structural plans of the building in concern. In many cases, those drawings/plans are not available and thus, a structural site survey is essential to gather required information and generate structural plans. Generally speaking, the site visits include measurement of the structural elements and assessment of their condition based on visual observations. On rare occasions, more laboratory tests, such as coupon tests to identify steel grade, may be required for more accurate results. - Select the racking & attachment system (ballasted, fully attached, or hybrid).

This step usually depends on the first step outcome since each solar system has different weight. The racking manufacturer should be able to switch solar system type based on recommended additional capacity provided from step one. - Check the feasibility of the roof structure to accommodate the PV solar system.

This step will be automatically met if the results from step one shows that roof structural members can have enough capacity to accommodate the solar system selected from step 2. The procedure begins to be intricate if the structural elements under their current status cannot accommodate the lightest solar system type. An advanced step, where the roof elements need to be retrofitted, is required in order to bring the solar project back to life!

Structural Element Determination Based on Site Visit Observation.

Increasing Capacity of the Existing Roof Structure to Accommodate the PV System:

There are three basic methods to strengthen structural element to increase its load carrying capacity:

- Load redistribution.

This method can be done by shifting the load from weak elements to stronger ones. Load redistribution usually requires adding additional elements that can safely transfer the load to stronger members. - Adding new elements.

New elements can be added to existing roof system by replacing some of the existing members with new ones which have higher capacity than that the original members have. This method imposes many hardships such as constructability issues (architectural elements are in place already), high labor costs, and may lead to delay in project deadline. - Reinforcing existing structural members.

This type of roof framing strengthening is considered ideal due to its low cost, short lead time, and constructability. The reinforcement can be done by adding additional members to the original one to resist the additional stresses imposed from the weight of the solar system components. Existing structural members should be in good condition to successfully apply this strengthening methodology.

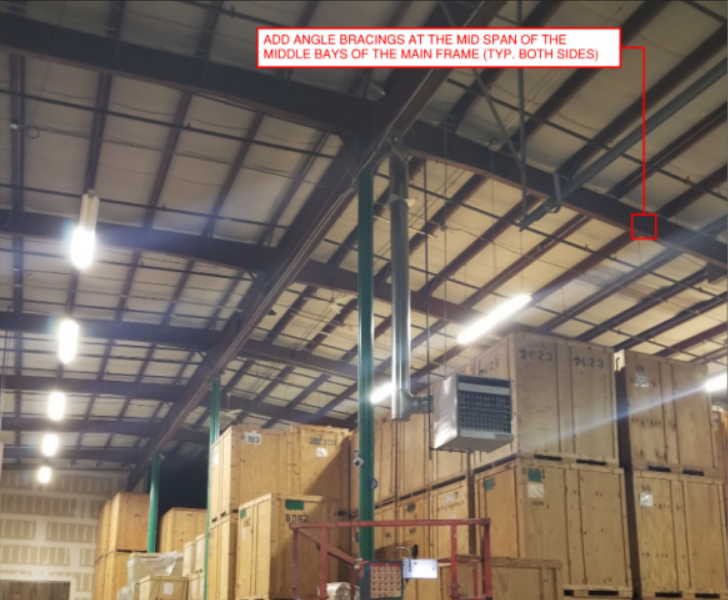

Location of Reinforcement From Inside Building Location of Reinforcement in Plan View

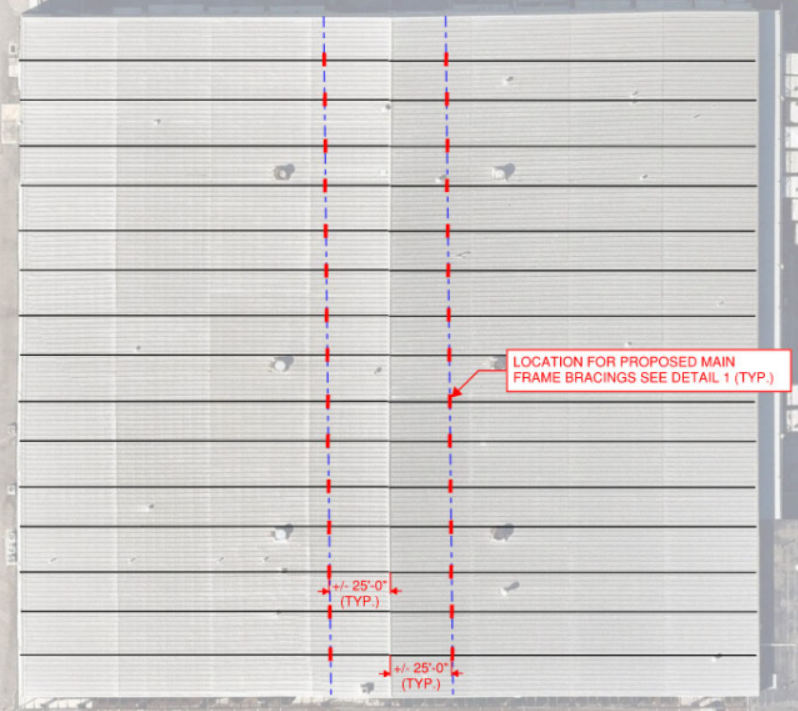

Location of Reinforcement in Plan View Reinforcement Detail to Increase the Capacity of Existing Roof Frame

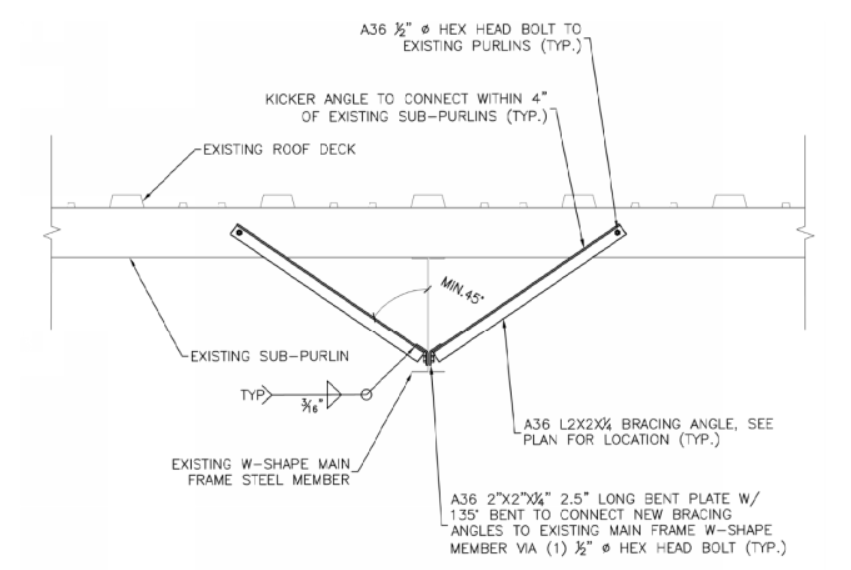

Reinforcement Detail to Increase the Capacity of Existing Roof Frame

Current Building Code Requirements:

Almost all states currently adopt International Building Codes (IBC) and International Residential Codes (IRC) with local amendments. Recent editions of IBC (2015 and 2018) dedicated specific sections for roof design with PV panels. It is worth mentioning that prior to 2015, there was no specific guidance for roof-mounted panel loading criteria. The new requirements imposed more complicated loading effects which the roof where the PV panels installed should meet. 2015 IBC and 2015 IRC states the following:

“1603.1.8.1 Photovoltaic panel systems. The dead load of rooftop-mounted photovoltaic system, including rack support systems, shall be indicated on the construction documents.”

“16.12.5.2 Where applicable, snow drift loads created by photovoltaic panels or modules shall be included.”

“R324.4.1 Roof live load. Roof structures that provide support for photovoltaic panel systems shall be designed for applicable roof live load”

“R907.2 Wind Resistance. Rooftop-mounted photovoltaic panel or modules systems shall be installed to resist the component and cladding loads specified in Table R401.2(2).”

Reading the above statements, both snow and wind loads should be included in the load combination now.

Another major code used by structural engineers to identify the applicable loads is ASCE. IBC 2018 adopts ASCE 2016 to determine the loading conditions. The latest ASCE version (2016) now requires the PV panels to be considered as dead load. This can cause major complication in determining the total system weight especially in high seismic regions. Also, live load should not be considered on the roof if the panels were placed at specific distances and heights. All those requirements are relatively new and were ambiguous to the design engineers. Top-rated consulting firms, that have the capacity to involve brilliant structural engineers, can facilitate economical and flowless design for PV panel installation on a roof of any building. A knowledgeable structural engineer who is well-rounded with the current building codes can identify and meet those requirements prior to construction phase, smoothen the design process, and minimize the overall cost of the solar project.

.png)