The strategic and efficient use of resources for PV system commissioning and operations and maintenance (O&M) are critical to optimizing solar PV power system revenue and profitability. Through our work as an Owner’s Engineer, Pure Power has formalized procedures for ensuring installation quality, and identified opportunities to streamline inspection and commissioning activities while minimizing risk.

When used properly, aerial imaging can benefit owners both before and after the commercial operation date (COD). Here I review the benefits of aerial imaging and share best practices for using aerial inspection services. In the process, I highlight some persistent myths that can lead to the inefficient use of resources or unnecessary exposure to risk of injury.

Benefits of Aerial Imaging in Large-Scale Systems

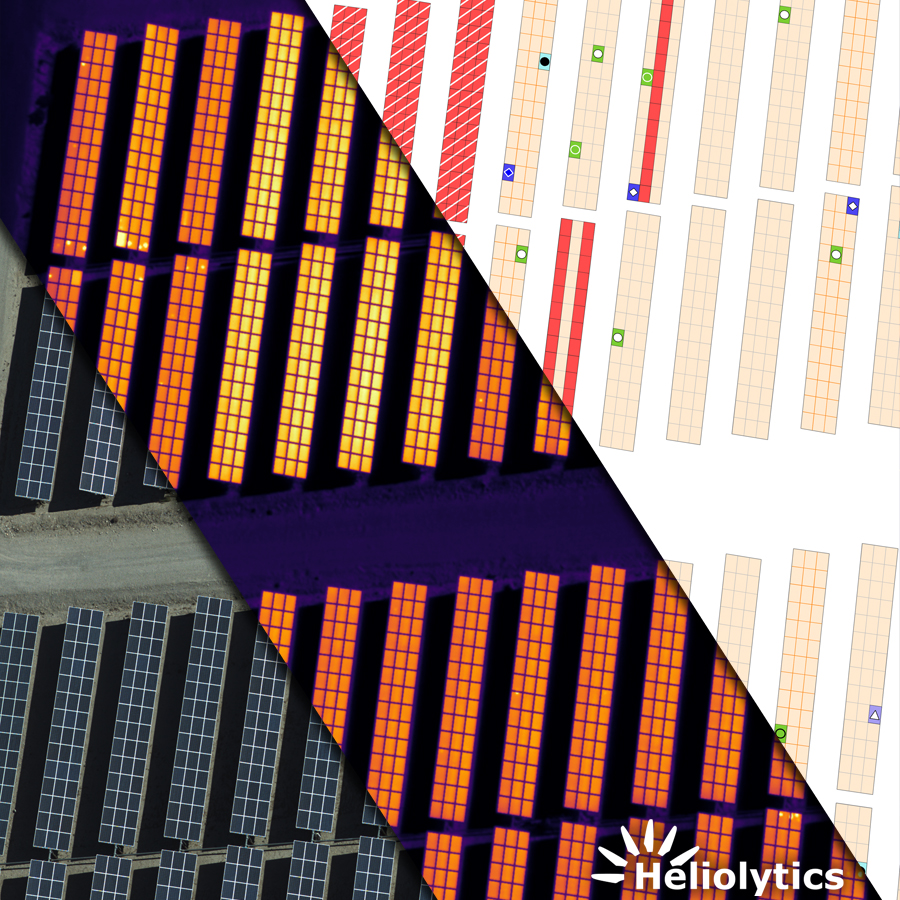

Aerial inspection services perform flyovers using manned or unmanned aerial vehicles or aircraft systems equipped with high-resolution cameras that collect visible and infrared (IR) imagery. The primary benefits of aerial imaging in this context relate to operational efficiency and site safety.

Courtesy Heliolytics

Operational efficiency. As compared to ground-based technicians or even drone-based aerial inspections, inspections conducted using piloted aircraft provide the fastest inspection times and produce the highest-resolution images. Changing weather conditions are one of the most challenging aspects of PV power plant inspections and performance tests. Piloted aerial imaging mitigates these issues by inspecting PV power plants at a rate of 150 MW per hour. It is much easier to compare inspection data across a site when it is captured over a period of minutes or hours rather than days or weeks. Moreover, aerial imaging identifies the precise location of potential issues by flagging individual strings, modules, or cells with atypical thermal signatures.

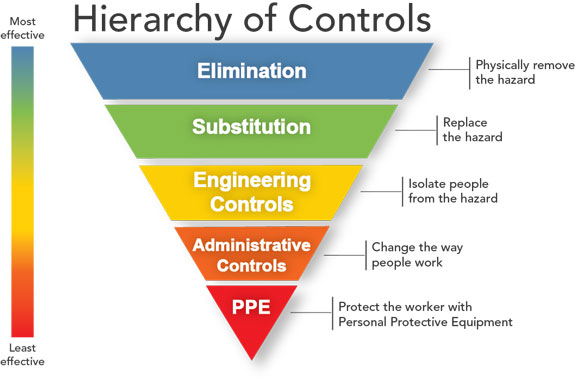

Site safety. Conducting aerial inspections in lieu of ground-based manual inspections is a highly effective means of reducing worker exposure to electrical hazards in accordance with the hierarchy of hazard controls. Since the DC circuits in a PV power system are energized whenever the sun is shining, there is no effective way to eliminate the electrical hazards intrinsic to the DC side of a PV power system. Therefore, the most effective way to control these hazards is to replace hazardous activities with nonhazardous activities. Replacing manual inspections with aerial inspections whenever possible is a perfect example of hazard control via substitution, as recommended by the National Institute for Occupational Safety and Health (NIOSH).

Pre-COD: Best Practices for Project Commissioning

Pure Power often provides Owner’s Engineering and IE services on new solar construction projects. In this role, we ensure that PV system performance and capacity tests are conducted in accordance with relevant industry standards, such as ASTM E2848-11 Standard test method for reporting photovoltaic non-concentrator system performance, as well as any other pertinent contract terms.

Boots-on-the-ground measurements are essential during project commissioning. It is impossible to conduct the voltage, polarity, I-V curve, and other tests required during pre-commissioning and commissioning without boots-on-the-ground resources

Myth #1: There is no reason to conduct an aerial inspection prior to COD.

Aerial imaging prior to project acceptance provides multiple benefits. Aerial inspections are an effective means of identifying infant mortality issues or installation deficiencies prior to EPC demobilization and walkaway. Moreover, the resulting data provides a snapshot of a fully functioning and healthy system that can serve as a baseline for subsequent aerial inspections. While aerial imaging may not be required to meet performance and capacity testing standards—and it cannot replace the manual tests required for project commissioning and acceptance—we recommend that clients conduct aerial imaging prior to COD as a best practice.

Post-COD: Best Practices for Project Operations

The benefits of aerial inspections are most acute after the commencement of project operations.

Myth #2: Periodic I-V curve tracing is the best way to inspect and assess the performance of operating PV power systems.

Many inspection contracts have legacy requirements regarding the manual collection of I-V curve traces and voltage measurements. These requirements are both outdated and misguided. Once a system is operating, I-V curve tracing is best used as a secondary inspection tool that is subservient to aerial and visual inspections.

As compared to manual inspections conducted by boots-on-the-ground resources, aerial inspections are faster, cheaper, and more predictable. In some cases, it takes no more than a minute and a single flyover to inspect an entire PV power system. The resulting digital record is very easy to interpret, especially when compared to challenges associated with interpreting I-V curves captured under changing weather conditions at different times of the day or week. Best of all, aerial inspections mitigate risk via substitution—by replacing an activity that requires exposure to energized electrical components with one that does not expose workers to these hazards.

Courtesy NIOSH

At Pure Power, we strongly recommend aerial imaging as a first-line inspection activity for operating PV power systems. Based on these IR images, we are able to gauge the frequency and pinpoint the locations of potential issues—including string-level failures, submodule failures, and cell-level hotspots—and strategically deploy boots-on-the-ground resources. Once a problem has been located and visually inspected, voltage measurements and I-V curve tracing are highly effective for troubleshooting and diagnosing these issues.

.png)

.png)

%20.png)