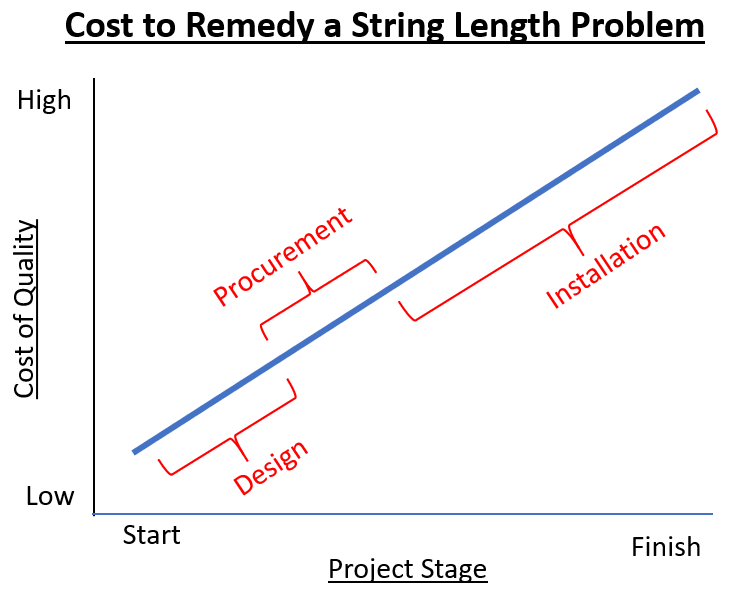

There is a well-known business adage called the “Cost of Quality”. This is a sliding scale that says, the closer to completion a project gets, the more expensive it is to fix quality issues.

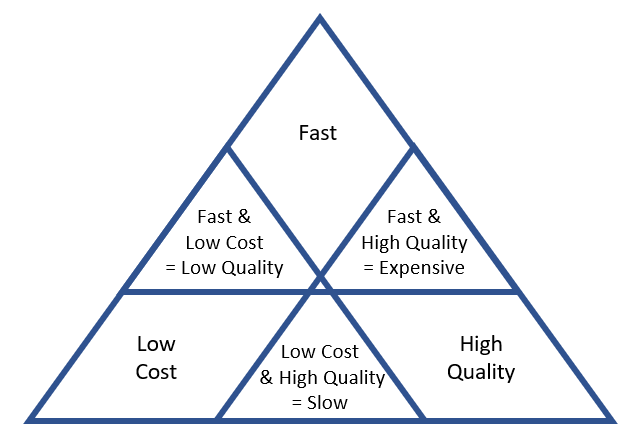

Quality comes in the form of Time (schedule) and/or Cost ($$$). Project Management textbooks call these the “triple constrains” as represented in the well-known triangle:

The old adage is you can maximize two but must sacrifice on the third.

All solar projects experience a design and construction cycle that must balance time, cost, and quality. As an Independent Engineer (IE), we never want to see a sacrifice in quality because the project ran out of time or money, but that is often the case when we conduct our review late in a project.

The problem with conducting an Independent Engineering review late in project:

Developers bring in engineers to satisfy the owner/lender’s desire do de-risk the project and ensure Quality. This is often done late in the project’s installation as a final sign off on the design and installation.

At this point, de-risking the project or remedying quality issues means more sacrifices to Time or Cost because the budgeted time and money has already been spent:

- Design is complete

- Materials have been procured and installed

- Installation labor has been expended

- Generation performance guarantees are set in the contract

The later in design and construction a quality issue is spotted, the greater the price time and/or money to restore the quality.

Example of the Cost of Quality: related to a string length miscalculation:

There was an error in the voltage calculations and the string length must be reduced. Below are three outcomes, depending on when the mistake was caught and corrected:

- Design Phase: The mistake can be remedied by re-drafting the design to the correct string length and racking table size. Extra effort by the engineer, but no effect of cost and negligible impact on schedule.

- Procurement: Once equipment is ordered, a change to the string length may affect inverter selection (# of string inputs) or table size. Equipment may need to be returned, reordered, or the design needs to be reworked in an non-ideal configuration to make the stringing work with the equipment you have. Time could be affected if equipment needs to be reordered, or costs will increase to make the design work with the equipment provided.

- Installation: Once the strings are wired up, correcting string length means uninstalling and re-installing the conductors. It may result in table sizes not matching string length so now you have the extra time and cost of inter-row jumpers. This will likely cause a delay in substantial completion, cost to rework, and a less-ideal design that may be harder to conduct O&M.

Minimize the Triple Constraints of Time, Cost, & Quality

The triple constraints of Quality, Time, & Cost holds true when owners and lenders hire an Independent Engineer. However, the ratio of Quality to Time & Cost is much different.

- Early IE Review: If problems are spotted early, the cost & time to remediate issues and achieve the desired quality is minimized. Stakeholders welcome the IE identifying all issues, as it can be fixed with minimal effect on Cost or Time.

- Late IE Review: When technical due diligence is performed at the end of the project, the price to remedy quality issues comes at the highest price in Cost and Time. Everyone is disappointed the IE did such a thorough job in locating quality issues.

Some may say “it’s the EPC’s responsibility to bear the expense of fixing problems”, which may be true for some direct costs, but all stakeholders experience increased OH, time, meetings, calls, fighting over LDs, etc. EPCs will also be more inclined to push back against some IE comments, resulting in many suggestions being ignored or shortcuts taken because the expense is too high.

Conclusion

Having an IE conduct their review early in the project life cycle adds value to the project.

The later the IE review, the more of a “check the box” exercise it becomes, and the value of the IE review is minimized.

If you are going to spend the money on an IE, get the most value and involve them early in the project.

.png)