When designing utility-scale solar energy projects, optimizing central inverters is a crucial aspect that project developers, EPCs, and stakeholders often overlook. The strategic placement and design of central inverters plays a significant role in maximizing the efficiency and output of utility-scale solar PV power systems. Ignoring these factors not only increases costs due to unnecessary expenditure on materials but also leads to reduced system efficiency. This, in turn, can cause a loss in power production and, in some cases, higher voltage drops across the systems.

Strategic Approaches to Central Inverter Placement and Design

Physical Placement Considerations:

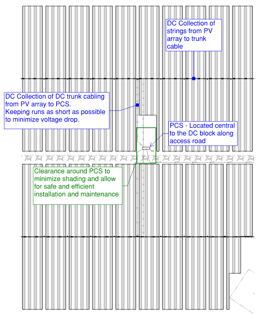

- Accessibility and Maintenance: Positioning central inverters along the access roads within the solar farm is a strategic move. This placement facilitates easier access for operation and maintenance (O&M) activities and simplifies the construction process.

- Equidistant DC Strings: Positioning each DC string equidistant from the inverter ensures minimal voltage drop across any one string. This uniform distribution helps maintain the overall efficiency of the power conversion process.

- PCS Height Consideration - It's important to factor in the height of the Power Conversion System (PCS) during the design phase, especially since PCS units can be quite tall on elevated pads. This height can lead to shading, which in turn reduces the efficiency of solar PV panels.

- Pad Selection - The optimal pad option should be chosen based on the specific conditions of the site. Available pad options encompass Concrete Pads, Steel Piles, Helical Steel Piles, Ground Screws, among others.

Electrical Design Nuances:

- Proximity to Roads for Medium Voltage Components: By situating the medium voltage portion of the inverter closer to access roads, the electrical circuitry can run parallel to the medium voltage pathways, reducing the complexity and potential interference with other circuits.

- Inverter Loading Ratio (ILR) Insights:

- The Inverter Loading Ratio (ILR), which evaluates the reduced AC size of the Power Conversion System (PCS) in comparison to its DC size should be above 1.0. Maintaining a ratio higher than this reduced value is essential for the PCS to function at its optimum capacity, fulfilling the Point of Interconnection (POI) requirements.

- Adhering to the optimum ILR values ensures that the inverters' full power capacity is utilized, preventing load flow issues and ensuring that the utility companies' power delivery commitments are met.

- Load Flow Analysis: Conducting a thorough load flow analysis is essential to confirm that the projected power delivery aligns with the utility's agreed-upon terms. It also verifies the adequacy of the number of inverters installed to meet power demand, thereby avoiding potential fines from utilities for under delivery.

Pure Power Engineering is the definitive choice for comprehensive engineering solutions, across utility-scale, commercial, and industrial solar and energy storage projects. With a seasoned team of engineers and project managers who have successfully spearheaded thousands of significant solar and storage initiatives, we are recognized as the industry's subject matter experts. Our suite of utility-scale engineering services is meticulously designed to cover every aspect of your project's lifecycle, including Development Engineering with up to 10% Optimization, Project Engineering at critical stages of 30%, 60%, and 90% Issue for Construction, advanced Structural Engineering & Pole Design, in-depth Power Engineering Studies, Glare Studies, as well as On-Site Inspections & Capacity Testing. For more information on our Utility-Scale Solar + Storage engineering services, please visit www.PurePower.com or email us at info@PurePower.com

%20(2).png)

.png)

.png)