Technical due diligence is essential to solar project success in commercial, industrial and utility applications. Large PV power systems are capital-intensive expenditures with a service life of 30 years or more. If these assets do not operate reliably and perform as expected, project financiers, owners and developers are at risk of reduced investment returns.

Mitigating risk over the operating life of a PV power system is more involved than simply meeting minimum requirements. As a consulting engineer to project owners and lenders, Pure Power has evaluated many troubled or underperforming solar assets that met minimum code requirements. These experiences have taught us that code compliance, as a legal minimum standard, is the only starting line for solar project due diligence—it is not the end goal.

Understanding Code Compliance

Like any structure or electrical system, PV power systems are subject to specific code requirements, such as the National Electrical Code (NEC) or the International Building Code (IBC). Meeting these code requirements is essential for permitting, inspection and limiting professional liability. In and of itself, however, meeting legal minimum standards does not guarantee quality, reliability, performance, serviceability or longevity.

Safeguarding versus adequacy. At a fundamental level, codes are an empirical reflection of the failures that have occurred in the field, especially those catastrophic failures resulting in loss of life, fire damages or large insured losses. The code authority represents a volunteer-based committee of subject matter experts and gathers a consensus of opinions and experiences about how in-field failures occur and may be prevented.

Since preventing loss of life and property are the primary focus of code-making activities, specific issues and deficiencies that result in reduced performance, serviceability or longevity are not at all covered by code. This limited scope is specifically defined in the codes themselves.

The very first entry to the NEC [90.1(A)] notes that:

“The purpose of this Code is the practical safeguarding of persons and property from hazards arising from the use of electricity.”

The following subsection [90.1(B)] acknowledges the limitations of code compliance:

“Compliance with [this Code] and proper maintenance result in an installation that is essentially free from hazard but not necessarily efficient, convenient, or adequate for good service…”

This caveat is an important distinction. In order to provide a good return on investment, a PV plant needs to operate efficiently, be convenient to maintain and have a long service life.

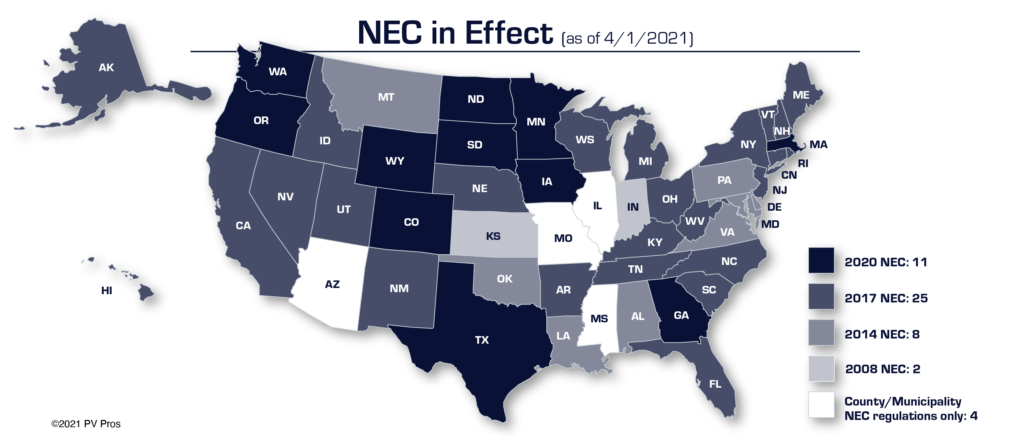

Variations between code editions. It is also important to recognize that code development and adoption move at the speed of bureaucracy rather than at the speed of technology or information. While new editions of both the NEC and IBC are published in three-year intervals, code adoption at the state or local level varies widely. These variations between code adoption schedules complicate the process of safeguarding persons and property.

Some states adopt new code editions immediately or in the same publication year. Other states wait a period of years before adopting the latest edition of the code. A few states may be enforcing editions of code that are more than 10 years old. Meeting minimum requirements in a jurisdiction that lags code adoption by several editions tests the premise that a code-compliant system is inherently free from hazards. In some cases, the lag between code adoption cycles and equipment evolution may actually prohibit the use of the latest technology.

Understanding Best Practices

Best practices are those means, methods and materials—in combination with experience or research—that are proven to produce superior results. Extending far beyond minimum legal requirements, best practices allow project stakeholders to make informed decisions based on metrics such as efficiency, effectiveness, adequacy and reliability. Best practices can and do vary based on stakeholder priorities and business models. Some organizations have short-term interests and asset divestiture in mind; other organizations own and operate assets and have long-term priorities. While investment horizons may differ, many best practices apply universally.

Performance matters. If a PV power system is not operationally available or operating efficiently, it will not provide the expected investment returns. Meeting minimum code requirements will not ensure against equipment failures, installation errors or design deficiencies. Consider, as an example, the interrelationship between ambient temperature and inverter selection and placement. High ambient temperature conditions may lead to inverter output power derating or reduced maximum power point tracking effectiveness. Excess heat may also cause nuisance tripping in overcurrent protection devices. Sizing code-minimum inverter output conductors may cause excessive voltage drop, resulting in nuisance tripping due to AC overvoltage. Best practices mitigate these types of performance risks.

Climate and location matter. If PV system designs are not responsive to environmental risk and adapted to location-specific perils—such as seismic loads, coastal high winds, snow and frost, or high heat and ultraviolet exposure—long-term performance and reliability may be compromised. Simply meeting code-minimum requirements may not protect against predictably severe weather. An engineering report presented to the Structural Engineers Association of California notes that:

“Structural failure of utility-scale PV plants are rare events, but some failures have been observed in code-compliant structures.”

While there is no protection against all extreme weather conditions, best practices improve system reliability and survivability relative to code-minimum designs. Understanding the impacts of frost heave and corrosion on foundations, coastal wind extremes or high-elevation snow loads can help with material and design choices to meet the longer project life target.

Installation and O&M matter. If a PV system is overly difficult for technicians to install or maintain, it may be further proof of the adage, “Penny wise, pound foolish.” Inverter placement is especially relevant in this regard. Spreading this equipment over many acres makes access more difficult and time-consuming when service is required. The best practice is to aggregate inverters into service clusters, effectively minimizing technicians’ time to access and service the equipment.

Low- or no-cost design adaptations—such as flexible conduit provisions that expedite inverter swap out—can provide significant savings during project operations. These are just a few of the many best practices that the experienced team of engineers at Pure Power bring to every project. These best practices ensure that your PV and energy storage systems are not only safe, but also adequate, reliable, efficient and profitable over the long term.

.png)