Workmanship and equipment warranties are the only thing that survive the passing of guardianship as a solar asset is developed, constructed and operated. Throughout a project’s lifecycle, different stakeholders pass the hot potato of responsibility from one party to another. While the names may change, the workmanship and equipment warranties remain. On the face of it, this is reassuring.

Working as an asset manager, however, I discovered that workmanship and equipment warranties are not the safety blanket that many believe them to be. Here I share some lessons learned while managing assets and supporting project owners and lenders.

Establish a Baseline in Year 0

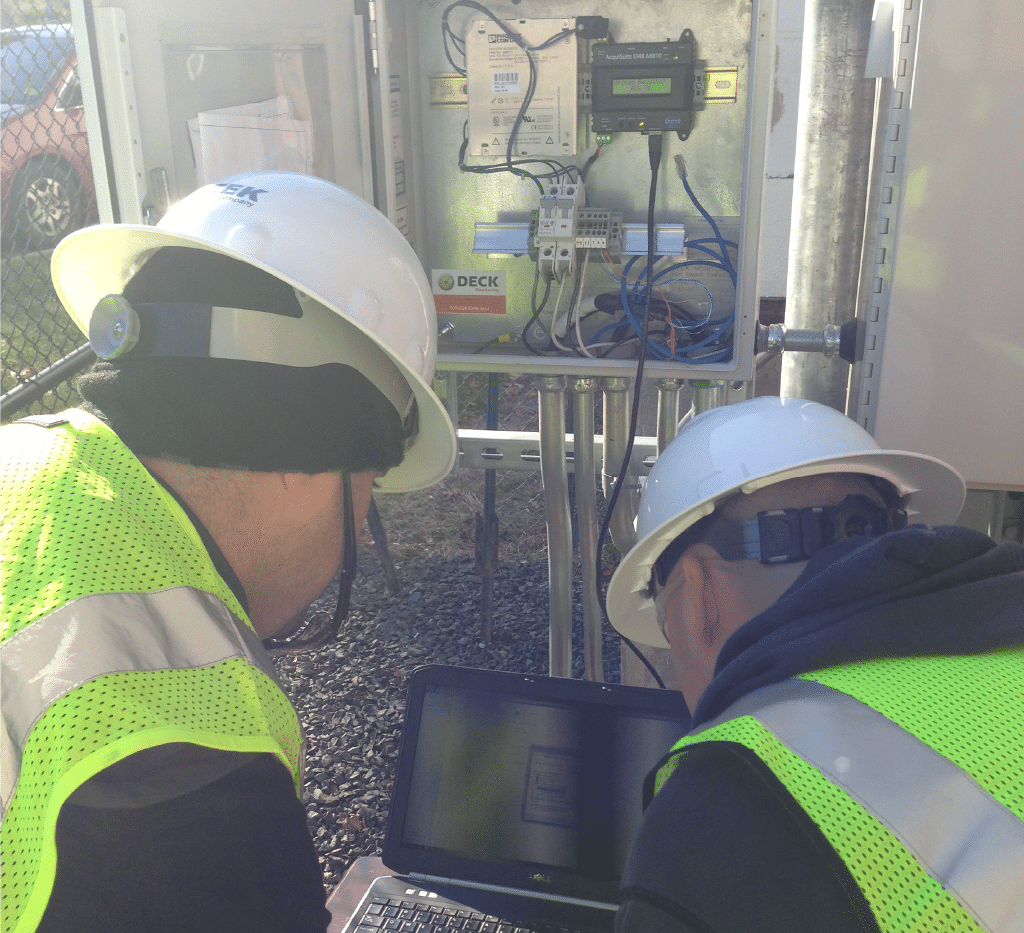

Thorough project documentation is essential to the success of future warranty claims. For best results, a thorough sweep of the site should take place right before handoff, perhaps as part of a mechanical completion milestone inspection. This inspection, in addition to providing a photo record of the as-built conditions, should produce a detailed summary of non-conformities related to workmanship; industry best practices; and discrepancies between the field installation and the design documents. Coupled with commissioning, capacity and performance test data, this documentation establishes a Year 0 baseline for the project.

In order to establish that a workmanship, equipment or O&M claim is warrantable, you must first document that the original equipment was properly installed. If you are unable to verify that the original installation used listed means and methods consistent with industry standards and the design drawings, you will not have success pursuing an O&M or OEM warranty claim during plant operations. While thorough documentation is crucial for warranty purposes, its importance is rarely reflected in contract requirements.

Use Your Leverage Wisely

For developers and asset owners, the EPC warranty is most effective as a lever during construction. If you want an EPC to remediate installation deficiencies, payments tied to major milestones—such as mechanical completion and final completion—provide a significant incentive. Do not give up this leverage prematurely, especially since the O&M warranty and major equipment warranties are contingent upon proper installation.

Once an EPC has demobilized a site or received final payment, the difficulty associated with remediation increases. Since it is impractical to call up an EPC warranty later, it is crucial that sites are deemed satisfactory while the EPC is still on site. Before cutting the final check, make sure that the EPC has addressed any workmanship issues and completed any QA/QC punch list items. Once final payment has been issued, you have effectively given up your last bit of leverage with the EPC.

Run a Cost-Benefit Analysis Against the Model

If my dad was a solar asset owner, he would be feared among EPCs. When faced with equipment or workmanship issues at his home, he is determined in his pursuit of compensation within the bounds of a given warranty. For a homeowner, given relatively low opportunity costs, this approach makes sense. For a solar asset, however, the opportunity costs of warranty pursuits must be considered.

If your business is owning and managing solar assets, this dogged pursuit of a warranties is often impractical and may even be counterproductive. In a world where every PV module is basically a dollar-generating machine, the first step of every repair is to conduct a cost-benefit analysis. On the one hand, you have an opportunity to save some money by pursuing a warranty claim. On the other hand, you have to consider lost revenue, as well as associated opportunity costs, sunk costs and O&M costs.

Not only is it difficult to make a successful claim against a warranty, but also the costs are non-negligible. So, even if you have warranty coverage, filing a warranty claim may not be the most efficient use of your time and money. Before pursuing a warranty claim, conduct a cost-benefit analysis based on the project’s financial model to ensure that you are not throwing good money after bad.

The Best Warranty is the Warranty You Never Need

Once a solar asset is operating, the outcome of a warranty claim is uncertain, especially in the absence of thorough documentation. Every warranty contains provisions that allow an O&M provider or OEM to push back on a claim due to installation deficiencies. Even if a warranty is enforceable, you will need to navigate and comply with a complex set of requirements in order to receive a payout.

Given the uncertain outcome, the best way to de-risk workmanship warranties and maintain equipment warranty limitations is to not rely on them in the first place. It is far more cost-effective to ensure that systems and components are installed correctly at the onset. This requires an independent third-party review conducted on behalf of the at-risk owner.

In my experience, qualified owner’s engineering services are essential to executing a successful warranty claim. Besides de-risking a warranty claim, engineering services are invaluable as a way to hedge off the hidden costs associated with jumping through warranty hoops. In addition to establishing an essential Year 0 baseline, a thorough pre-handoff inspection ensures that installed systems are not only warrantable but also less reliant on an uncertain warranty claim process.

.png)

.png)

%20.png)