Torque is a commonly used term in Solar PV system inspection, which refers to the act of tightening a mechanical fastener. The fastener can cover a wide array of details, not limited to attaching structural members, electrical connection and weather tight seals on conduit and enclosures.

Why is This Important for Owners and Financiers?

Under torqued fasteners are a common root cause for catastrophic electrical and mechanical failures and are one of the easiest issues to prevent. Diligence during construction and O&M activities can eliminate this issue entirely.

How Hardware Fails

There are two failure categories for torqueing:

Over torque – where the recorded tightening exceeds the specification, this can lead to:

- Galled hardware, where the bolt/nut weld together. This requires the bolt to broken in order to remove.

- Stressed hardware, where the material limits are approached, and leads to premature failure.

- Deformation, where the bolted connection becomes crushed and damaged.

Under torque – where the recorded tightening falls below the specification, this can lead to:

- Hardware can come apart under environmental stresses (like wind and snow)

- Electrical connections can become hot, and lead to arcing or fires.

How to Set Up for Success

A few key takeaways to note:

Step 1 – Documentation and Planning for Construction

Success starts with the documentation and tools during construction. We look for:

- All torque values clearly identified in the respective drawing sets or installation manuals for each task and fastener type.

- All tools used should be properly matched and calibrated to the specific task.

- Avoid battery powered tools unless they have an under-torque lockout, to prevent under-torque due to low tool battery voltages.

Step 2 – Maintain Diligence During Construction QC Inspections

Proper quality control methods are integral with the construction.

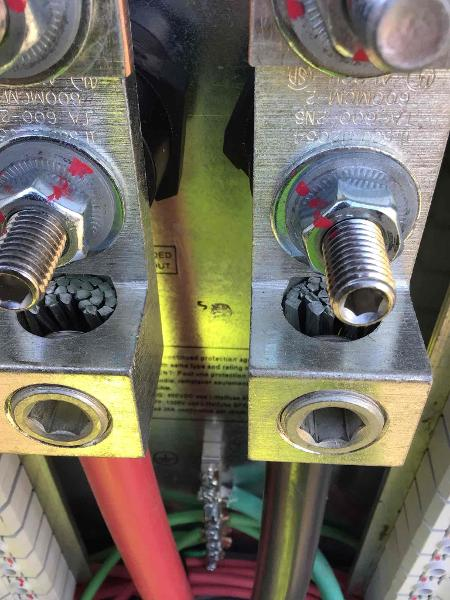

- Mark all tested connections as they are tested to reduce the gap between the inspection and the work performed.

- Mark mechanical connections with a UV rated paint marker. This ensures the QC marks will be visible for years.

- Mark electrical connections with a QC gel. This ensures any tampering will be visually notable and should trigger a reapplication of the connections.

- Maintain test records, with clearly identified target limits and pass/fail notes with photos when failures occur.

Step 3 – Long Term Inspection and Maintenance

The final step is confirming the long-term health of the system. What we look for:

- Use of Infra-Red (IR) thermal scans to ensure hotspots don’t creep up over time.

- Visual inspections for signs of wear and tear or corrosion on mechanical fasteners.

What are the biggest critical to quality pitfalls related to torque?

Eliminate re-torque from the maintenance vocabulary for electrical connections. Torquing should be considered a one-time event. Better to use IR scans to identify under-torqued hardware that needs re-torquing.

Who Can Ensure Torquing is Done Correctly?

Pure Power has Field Engineers that specialize in QC inspections, commissioning, and construction monitoring. We will ensure your installer is using proper torquing practices.

.png)

.png)

%20.png)